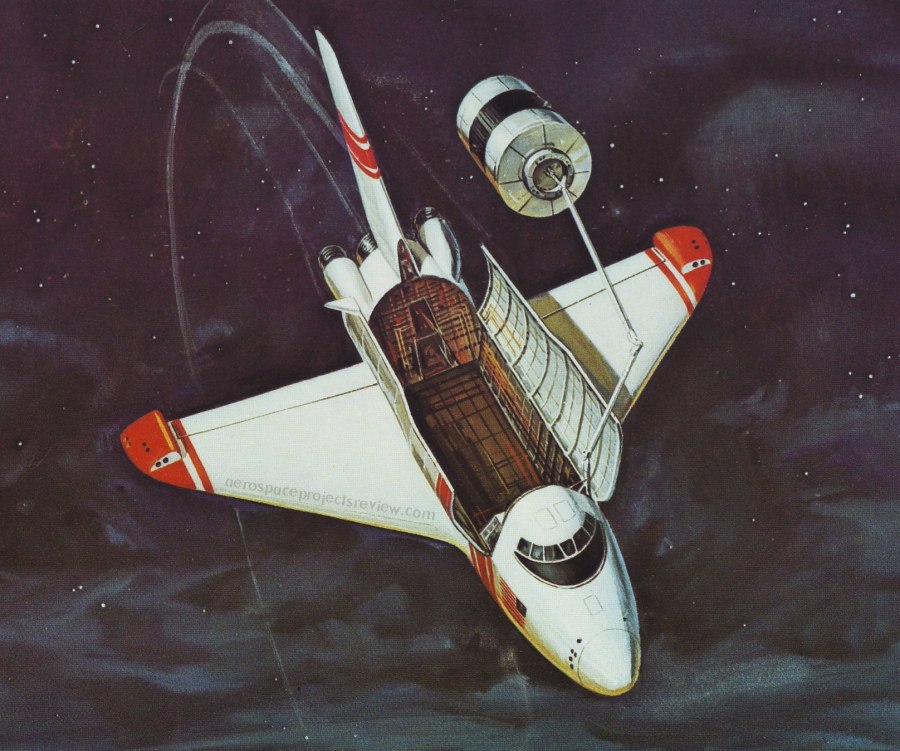

A plexiglas display model of the Grumman design 619 space transportation system showing interior arrangements and details. Note the turbojet pods packed into the rear of the cargo bay and the hump atop the forward cargo bay… providing space for the remote manipulator arm.

An illustration of Grumman’s 619 Space Shuttle – the final competitor for the competition that North American Rockwell won – lifting off. This design from 1972 was laid out pretty much as the final Space Transportation System was, but with some notable differences:

1) Stabilizing fins on the external tank

2) A “humped” back

3) four turbojet engines could be stored in the rear of the cargo bay, used for landing range extension, go-around capability and self-ferrying

4) Smaller OMS pods

5) Separate reaction control pods on the wingtips

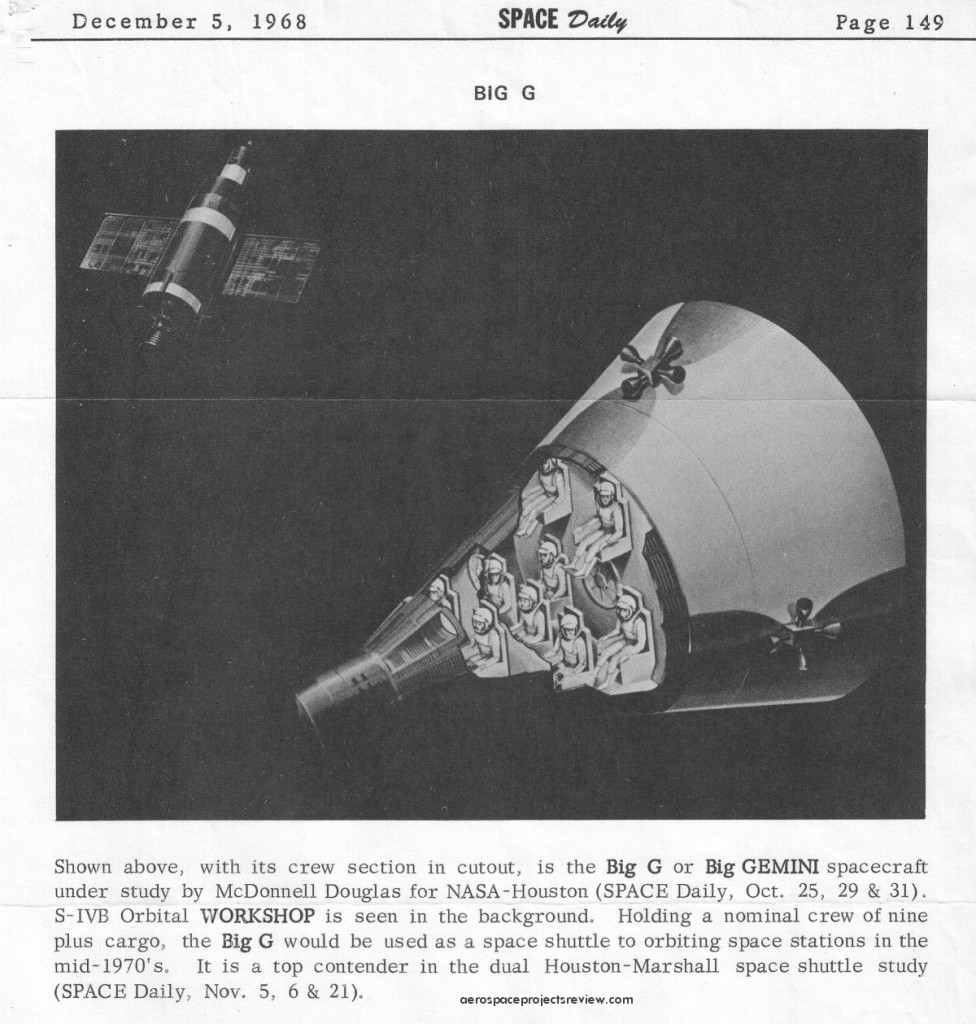

One pre-Shuttle idea for a space logistics vehicle was the “Big Gemini.” This would have used portions of the Gemini re-entry capsule as the nucleus around which a much large conical capsule would be built. The adapter section would be done away with and replaced with a conical section (with a geometry matching and extending the Gemini capsules) to house a variable number of passengers. A large number of “Big G” configurations were put forward; generally these were to be launched atop the Saturn Ib, but Saturn V and Titan IIIc options were also studied.

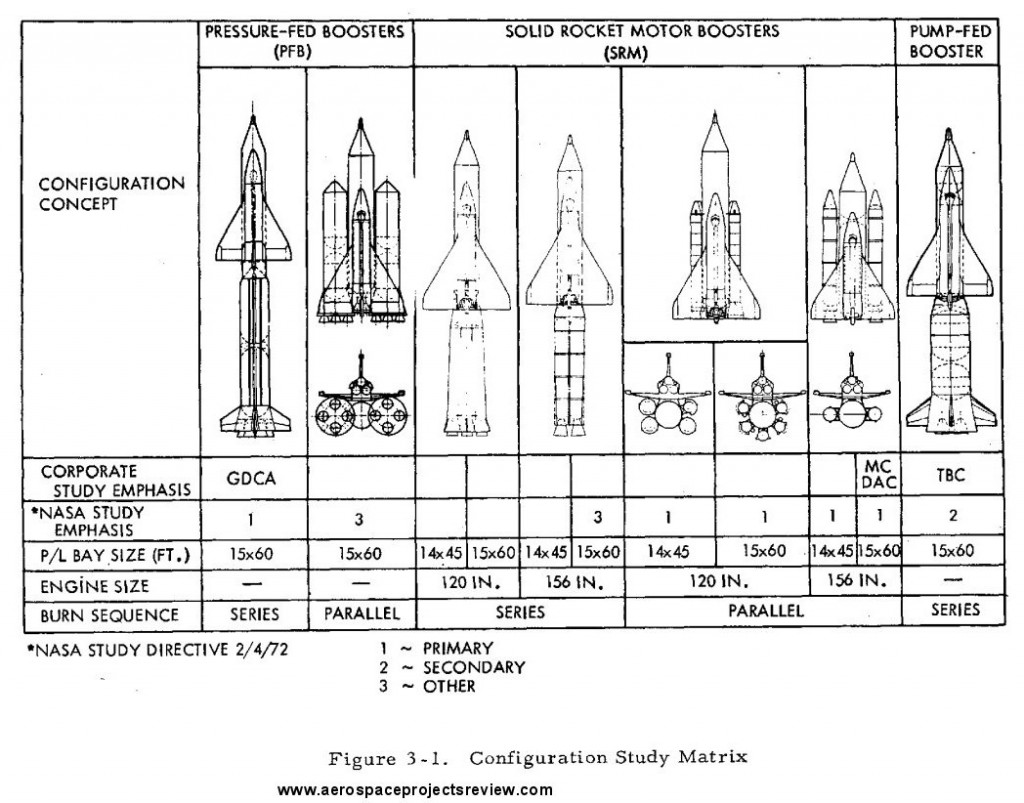

A collection of designs produced for alternate space shuttle configurations. This was the last gasp for configurations substantially different from what actually got built…. the second design from the far right became the baseline layout. But even with a recognizable orbiter and external tank, considerable variation was possible in overall launch vehicle layout. Not shown is a flyback booster option.

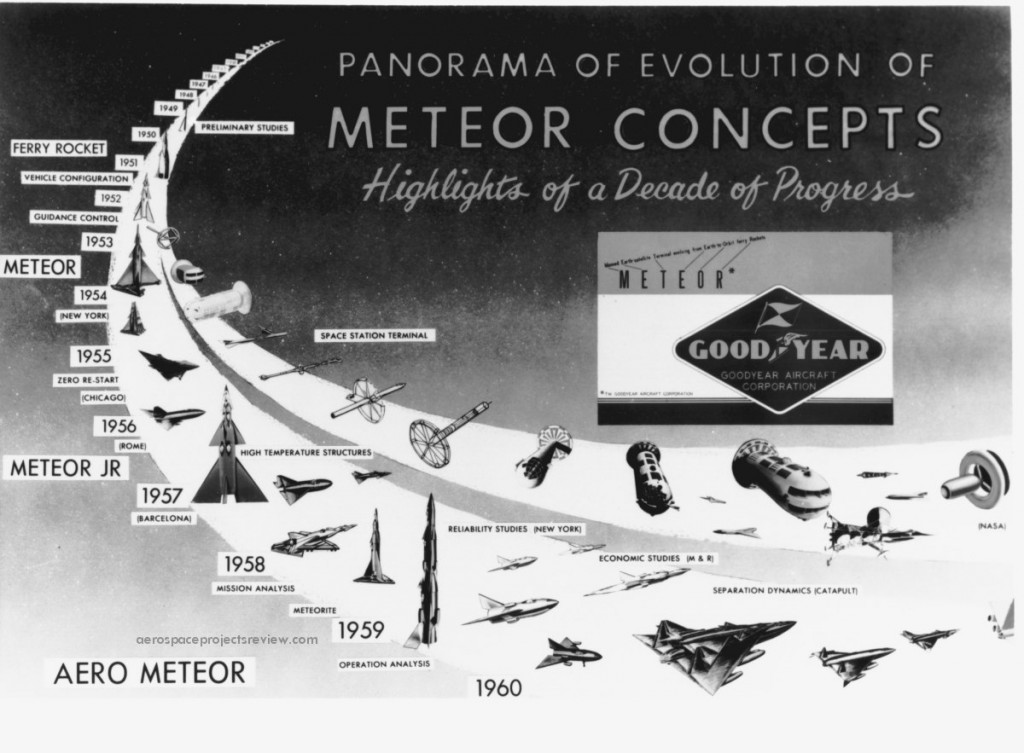

An illustration from Goodyear, circa 1960, showing the evolution of the “METEOR” launch vehicle and space station systems. Note that it goes back to at least 1949, and perhaps earlier. See also Space Doc 55.

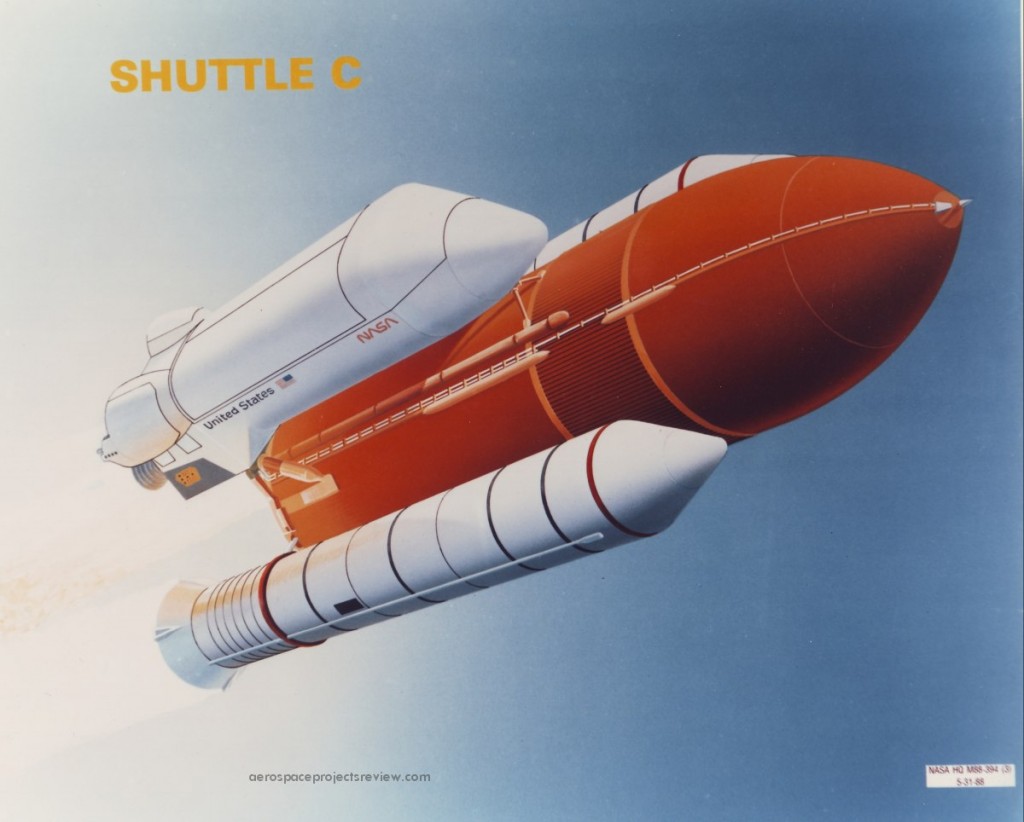

A NASA illustration from 1988 depicting a Shuttle C launch vehicle in flight.

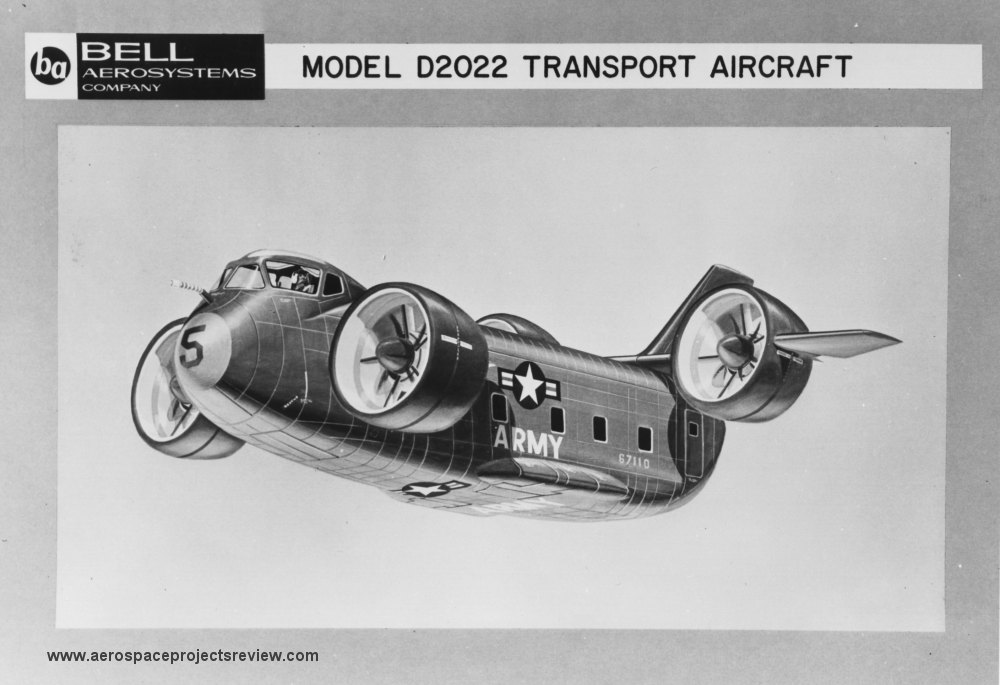

A 1959 Bell Aerospace design for a Tri Service (Army, Marines, USAF) VTOL troop transport using vectorable ducted fans. This obviously led to the X-22 design. The fuselage was much like that of transport helicopters like the Chinook, boxy and unaerodynamic, but the propulsion system would provide considerably higher forward velocity.

A chart of Bell VTOL designs is HERE.

A Grumman alternate Space Shuttle concept with a low cross range orbiter and a trio of 156-inch diameter solid propellant rockets for the first and second stages. The orbiter itself was stuffed with liquid hydrogen and liquid oxygen tanks; even so, the high density of the solid rockets meant that the vehicle as a whole was remarkably compact.