The “Firefly α” (“Firefly Alpha“) is a proposed small expendable launch vehicle, payload 400 kilograms. What is supposed to set the design apart:

1) Methane for fuel

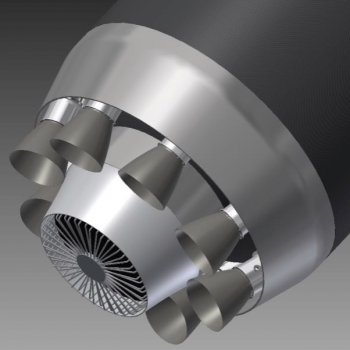

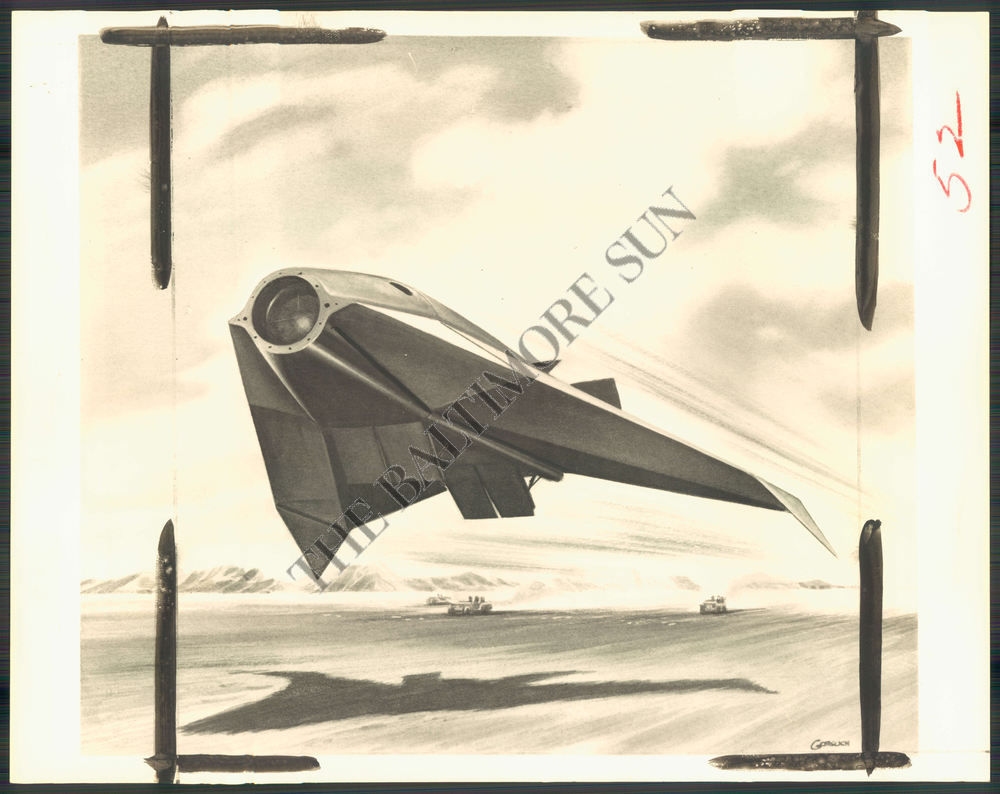

2) A plug cluster first stage engine

Methane has been repeatedly proposed over the decades for boosters, but it has never been used. It has higher Isp than kerosene and similar heavy hydrocarbons, but at the expense of low density and being cryogenic.

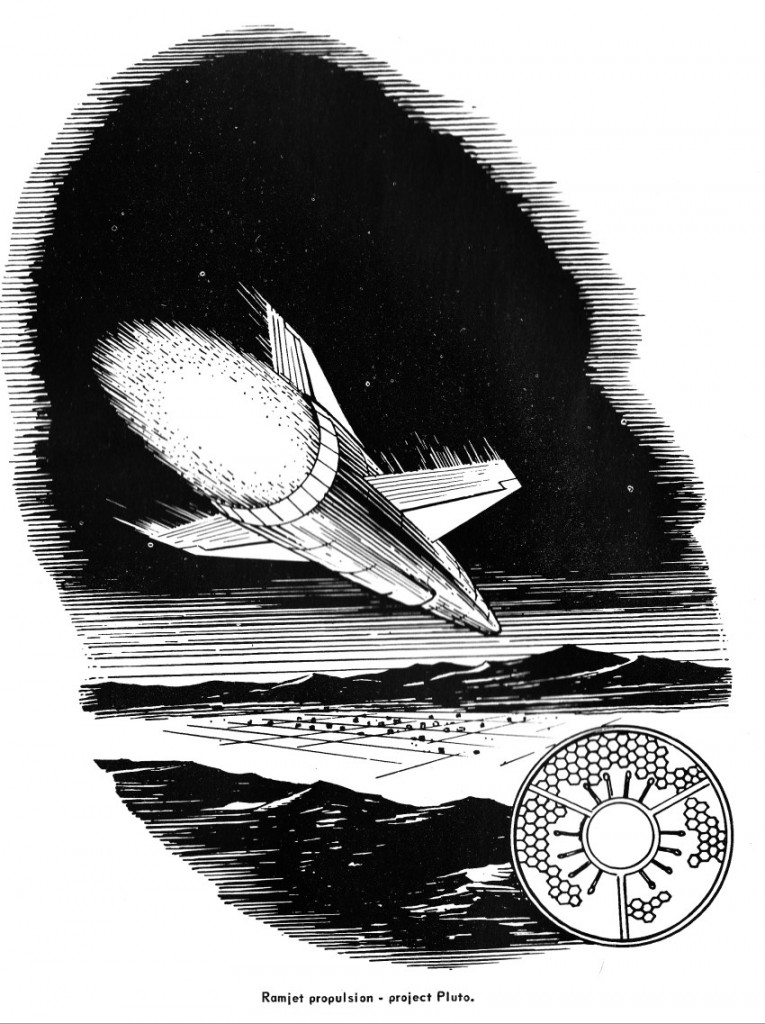

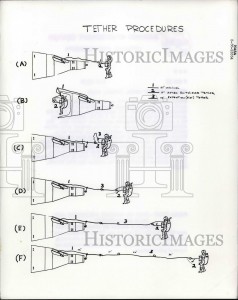

The plug cluster engine has also often been proposed. The idea: take a large number of small rocket engines and arrange them in a circle (well, as close to a circle as you can get with a finite number of points). Instead of pointing them straight aft, point them ten or so degrees inwards, and put a “plug” in the middle of them. The rocket exhaust then expands against the plug. What you end up with is a simpler version of a toroidal aerospike. The advantage is that you don’t have to develop a really big engine, just a number of smaller ones; and your booster engine now has automatic altitude compensation. This can be a serious issue for first stage boosters; they lift off at sea level and can fly virtually to the vacuum of space, and a rocket engines performance is driven in no small part by how well it compensates for the surrounding atmospheric pressure. If the rocket nozzle it optimized for maximum vacuum performance, this means that the pressure in the exhaust as it expands through the widening nozzles, drops below atmospheric pressure at some point. This can not only rob the nozzle of performance, it can also collapse, crushed like a beer can hooked up to a vacuum pump. A nozzle optimized for sea level, which has the exhaust reach sea level pressure more or less right at the exit plane, works fine all the way to space, but there is a lot of wasted impulse. An aerospike or a plug cluster automatically compensates, so a properly designed engine gets best performance all the way.

The problem: that central plug gets *hot.* Hot enough that cooling is a major, heavy and expensive issue. Further: plug clusters only approximate true aerospikes. Performance can be kinda… meh. The illustrations of the FRE-1 engine look like the performance benefit of the central plug will be minor… the individual rockets have fairly substantial nozzles on them, while the plug only seems to contribute a fairly small additional amount due to its short length. A caveat: truncated plugs can benefit from “virtual” plugs, and that seems to be what’s going on here. If you inject a gas into the central portion of the plug, the rocket exhaust will pressurized said gas, pushing on the engine. The result is much as if you had an actual physical plug… but one you don’t have to worry about overheating. The way this is normally designed, the turbine exhaust from the pumps powering the engines is dumped into the center to for the gas-plug. A dandy way to use turbine exhaust gasses you were just going to dump overboard anyway. But the Firefly is a pressure fed system: the LOX and methane propellants are going to be allowed to boil in their tanks to provide the pressure needed to push the propellants into the engines. So… no turbine exhaust. No spare gasses at all, actually.

Also: autogenously pressurized system like this have another issue. By definition, the liquid propellants being pushed through the system are just a hairs breadth away from boiling. So when they pass through the rocket engin injectors and undergo a pressure drop… they boil. or simply flash straight to gas. If this happens in the combustion chamber… great! But the math shows that this wants to happen in the *injectors.* And what happens is that gas bubbles form in the tiny injector ports, mucking up the works. The easiest way to make sure this doesn’t happen is to carry along pressurant gas like helium. Most of the tank pressurization still comes from the cryogenic propellant boiling, but an additional few (dozen?) PSI are added by the helium. This gives the propellant just enough buffer to make sure it gets all the way through the injector before bubbles form.